What are the issues to pay attention to when using a dual liquid glue filling machine?

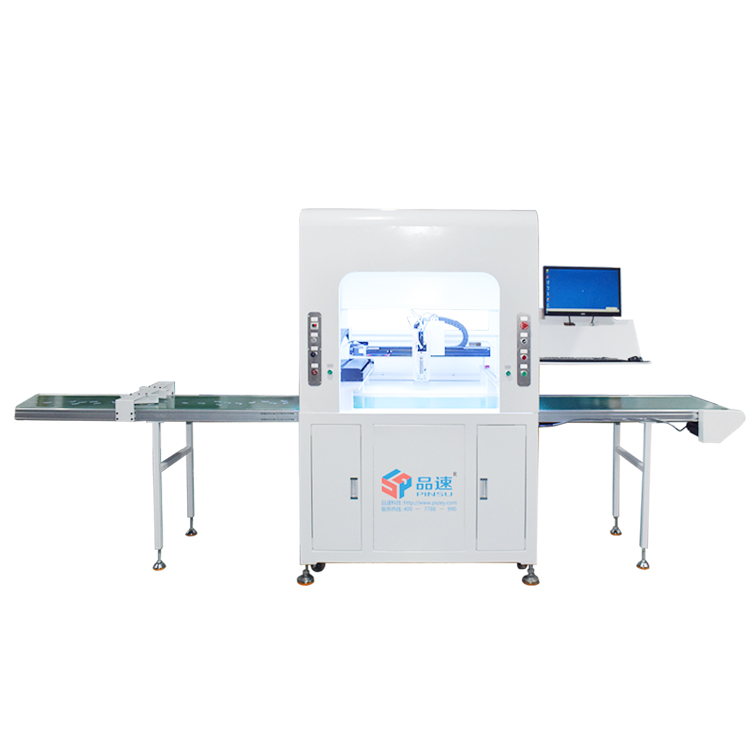

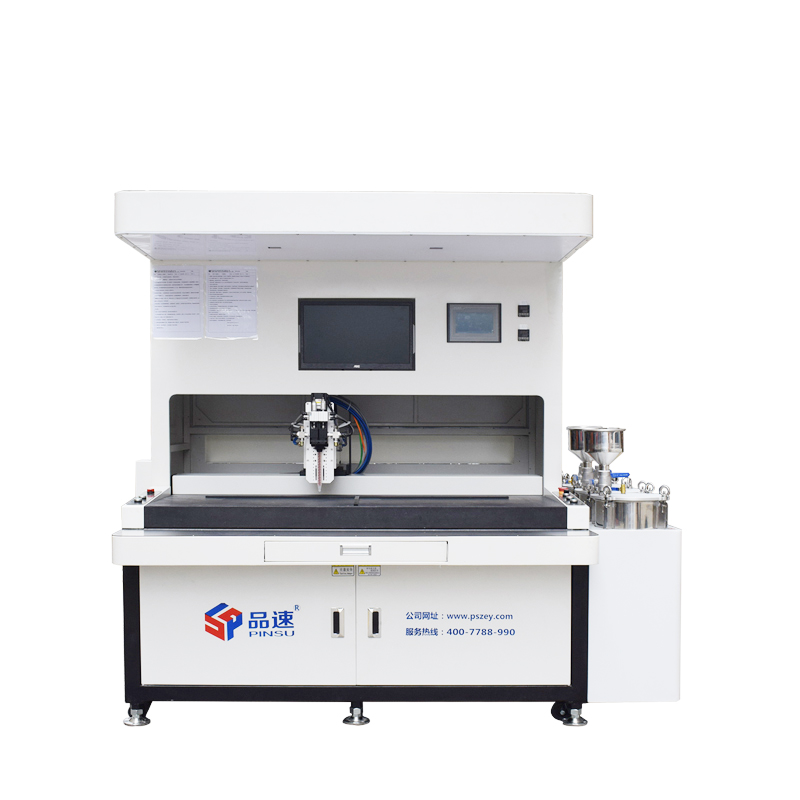

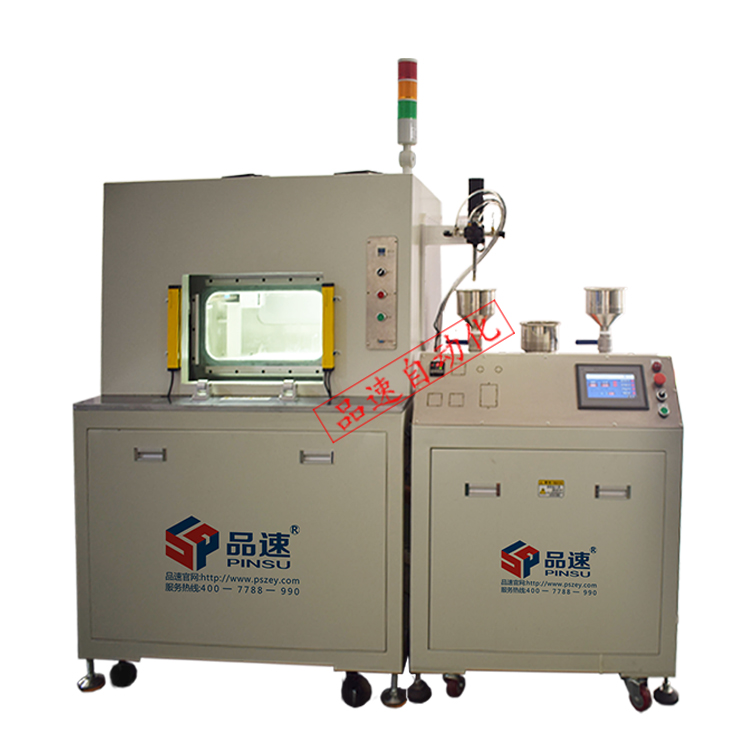

The dual liquid glue filling machine has a relatively fast glue filling speed and can automatically stop filling without excessive manual intervention. There are several issues to be aware of during use.

1. If there are bubbles in the glue, it is necessary to evacuate and remove them immediately, so that the glue poured out will have no bubbles;

3. Before gluing, measure the glue ratio several times to see if it is accurate;

4. If there is no problem with the glue ratio, put the glue in the oven and bake at 60 to 80 degrees for 20 to 30 minutes to see if it will dry. Some operators have measured the glue ratio, but forgot to turn on the mixing, and the glue is black, so it cannot be seen. If the glue is not stirred, it will definitely not dry when poured out. In the mixing process, to avoid problems, the glue filling machine is equipped with an alarm function in the software. Assuming that the mixing core is not rotating, the machine will sound an alarm prompt.

In short, the dual liquid glue filling machine has accelerated the industrialization process, and as its application scope becomes wider, the direction towards intelligent development will be the future.

1. If there are bubbles in the glue, it is necessary to evacuate and remove them immediately, so that the glue poured out will have no bubbles;

2. The surface of adhesive products should be kept clean, as some products may react with moisture on the surface of the adhesive, resulting in the formation of bubbles; Some products have not been cleaned thoroughly on the surface, which may cause the substances adsorbed on the product to react with the glue, resulting in the glue not drying when poured out;

3. Before gluing, measure the glue ratio several times to see if it is accurate;

4. If there is no problem with the glue ratio, put the glue in the oven and bake at 60 to 80 degrees for 20 to 30 minutes to see if it will dry. Some operators have measured the glue ratio, but forgot to turn on the mixing, and the glue is black, so it cannot be seen. If the glue is not stirred, it will definitely not dry when poured out. In the mixing process, to avoid problems, the glue filling machine is equipped with an alarm function in the software. Assuming that the mixing core is not rotating, the machine will sound an alarm prompt.

In short, the dual liquid glue filling machine has accelerated the industrialization process, and as its application scope becomes wider, the direction towards intelligent development will be the future.

中文

中文