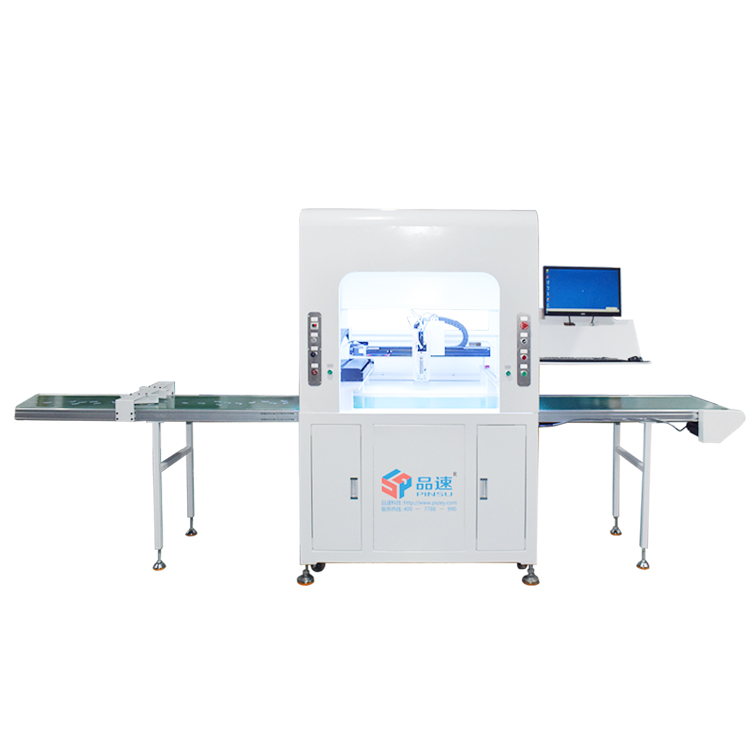

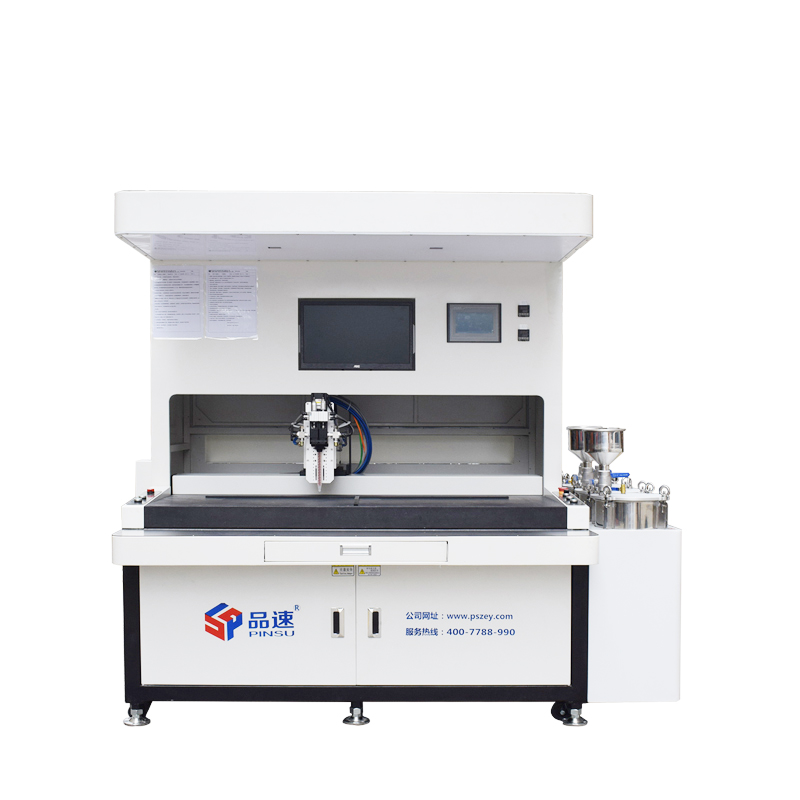

What are the effects of weather on Dispensing Machine Dispensing

Major factors affecting glue of glue dispenser and dispensing machine due to seasonal climate. It mainly includes the change of environment humidity and temperature. Specifically, in spring and summer, especially in plum rain season, the relative humidity of air is relatively large, even reaching saturation, while in autumn and winter, the air is dry and the humidity is small; In terms of temperature, the temperature in summer is much higher than that in winter, and the maximum difference between the two can be close to 30-40 ℃ (here is the southern area without indoor heating for comparison).

First, for two-component urethane adhesives commonly used in dispensing machines, moisture can react with the NCO groups in the curing agent as the host agent, polyester/polyether polyols. It is estimated that 26~32g of curing agent can be consumed by 1g of water. Of course, in terms of the pure reaction weight ratio, in practice, the water mixed into the working glue solution is competitive with the main agent when reacting with the curing agent. However, no matter how much water is involved in the reaction in the end, it undoubtedly consumes the curing agent, so that the amount of its reaction with the main agent cannot reach the original working ratio, thus causing incomplete curing and residual viscosity. The viscosity and reactivity of adhesives are strongly related to temperature. The viscosity value given by the adhesive manufacturer is measured with a rotational viscometer at a standard temperature of 25 ℃, which means that the working environment temperature can be more than 10 ℃ higher in summer and more than 20 ℃ lower in cold winter. The viscosity of glue is just opposite to the temperature, that is, when the temperature is high, the viscosity value of the same glue is low, the flow dispersion performance is good, and when the temperature is low, the viscosity is high, and the flow adjustment is poor. In addition, the cross-linking and curing reaction between the two components of the adhesive is slow at low temperature and fast at high temperature, which is precisely why there is a curing room (accelerating the curing reaction and improving the production efficiency).

In view of this situation, the following adjustments can be made for the environmental change of the two-component polyurethane adhesive when using the dispensing machine: if the air is wet and the temperature is relatively high, the amount of curing agent shall be appropriately increased by 10% - 20% to compensate for the water consumption; Always use dry cotton yarn or cloth to absorb condensed water drops on the compounding machine to prevent them from falling into the glue pot; A small amount of solvent can be added to dilute the working glue that is not used completely, and then it shall be sealed for storage. If conditions permit, it can be stored in a small refrigerator, so that the effect is better. When it is used next time, it shall be unfrozen in a closed condition and mixed with the new working glue. When the temperature is low in winter, more solvent can be added properly to prepare the working glue solution to reduce the viscosity of the system, improve the flow dispersion and reduce the generation of bubbles in the glue basin during working. However, in this way, the concentration of the working glue will be reduced. If you do not want to change the working concentration, you can use a small amount of acetone to replace part of ethyl acetate, that is, use the mixed solvent of acetone and ethyl acetate as the diluent, and the ratio of the two can be 2:8 or 3:7.

中文

中文