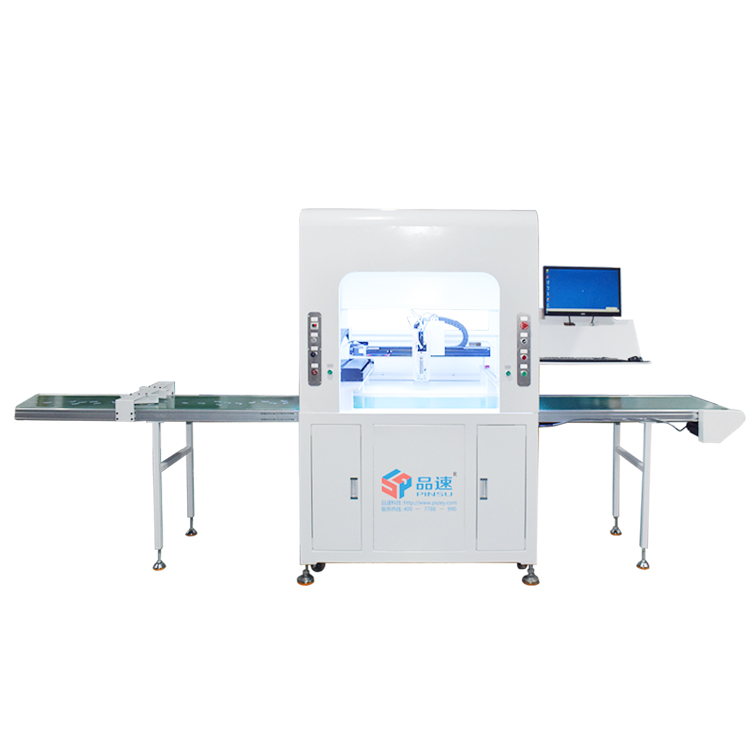

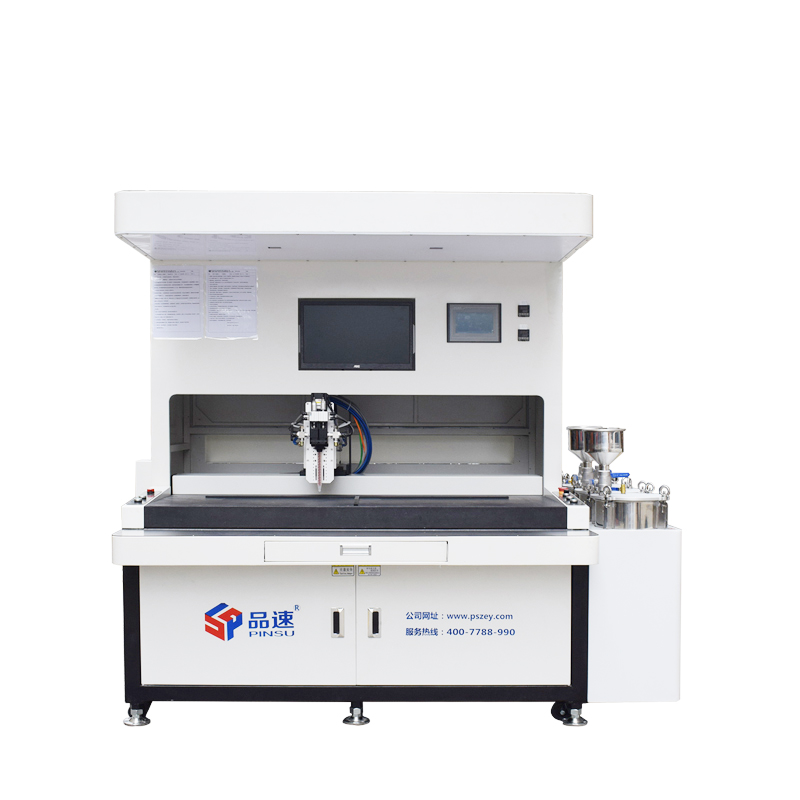

Maintenance tips for automatic glue filling machine

Potting machines are mainly used to produce industrial products and electronic equipment. How should we maintain them during use to ensure their normal operation and extend their service life? The following are some maintenance tips for the glue filling machine, and I hope they can help you.

1. Regular cleaning: the glue filling machine shall be cleaned regularly to prevent dirt and glue from accumulating inside the machine. When cleaning, use soft cloth and cleaning agent to avoid corrosive cleaning agent.

2. Keep dry: The glue dispenser shall be placed in a dry and ventilated environment to prevent moisture and fungus growth. If the potting machine is in wet environment for a long time, it may cause circuit failure or rust of mechanical parts.

4. Glue replacement: the glue used by the glue filling machine shall be replaced regularly to ensure the quality and effect of glue. The glue shall be replaced according to the operating instructions of glue filling machine.

5. Regular maintenance: the glue filling machine needs regular maintenance to ensure its normal operation and extend its service life. During maintenance, replace the vulnerable parts, clean the inside of the machine, check the circuit and mechanical parts, etc.

In a word, the maintenance of glue filling machine is very important to extend its service life and ensure its normal operation. If you are not familiar with the maintenance skills of the potting machine, it is suggested that you consult the potting machine manufacturer or professional maintenance personnel for more help and guidance.

1. Regular cleaning: the glue filling machine shall be cleaned regularly to prevent dirt and glue from accumulating inside the machine. When cleaning, use soft cloth and cleaning agent to avoid corrosive cleaning agent.

2. Keep dry: The glue dispenser shall be placed in a dry and ventilated environment to prevent moisture and fungus growth. If the potting machine is in wet environment for a long time, it may cause circuit failure or rust of mechanical parts.

3. Regular inspection: the glue filling machine shall be inspected regularly to ensure its normal operation and extend its service life. During inspection, check whether the circuit, mechanical parts and glue conveying system operate normally.

4. Glue replacement: the glue used by the glue filling machine shall be replaced regularly to ensure the quality and effect of glue. The glue shall be replaced according to the operating instructions of glue filling machine.

5. Regular maintenance: the glue filling machine needs regular maintenance to ensure its normal operation and extend its service life. During maintenance, replace the vulnerable parts, clean the inside of the machine, check the circuit and mechanical parts, etc.

In a word, the maintenance of glue filling machine is very important to extend its service life and ensure its normal operation. If you are not familiar with the maintenance skills of the potting machine, it is suggested that you consult the potting machine manufacturer or professional maintenance personnel for more help and guidance.

中文

中文