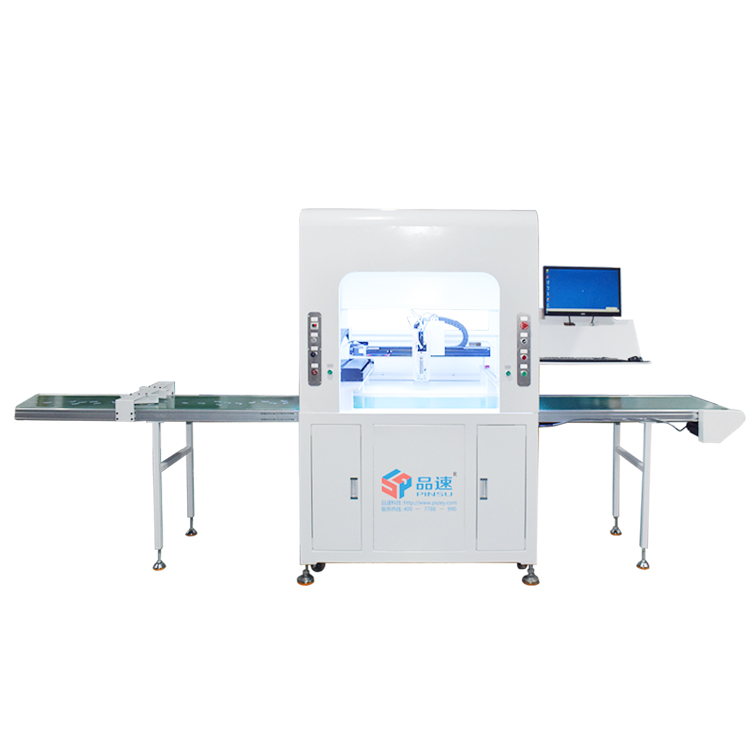

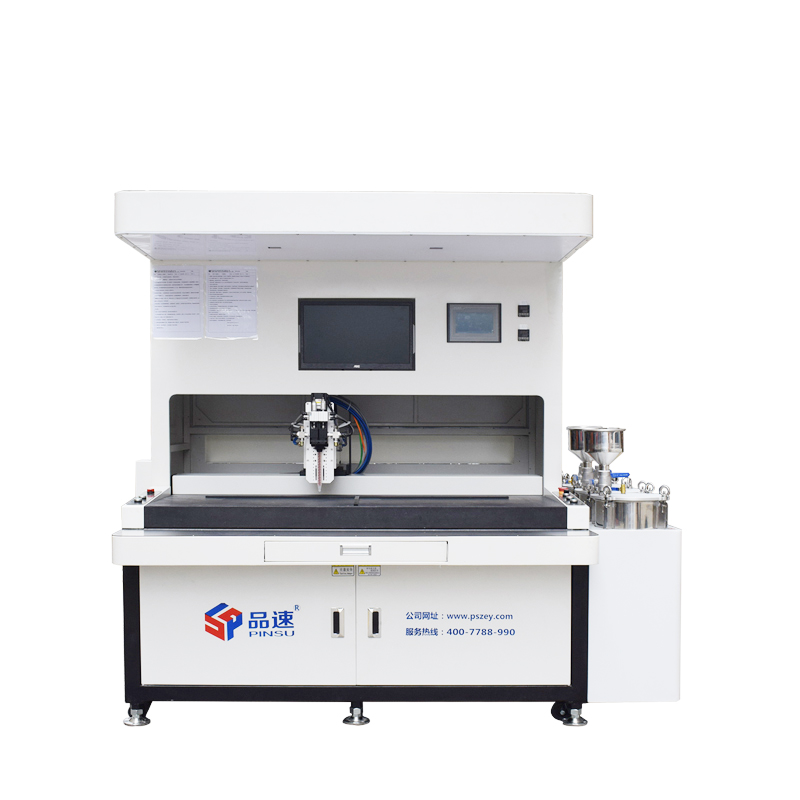

What are the factors that affect the operation of the dispensing machine?

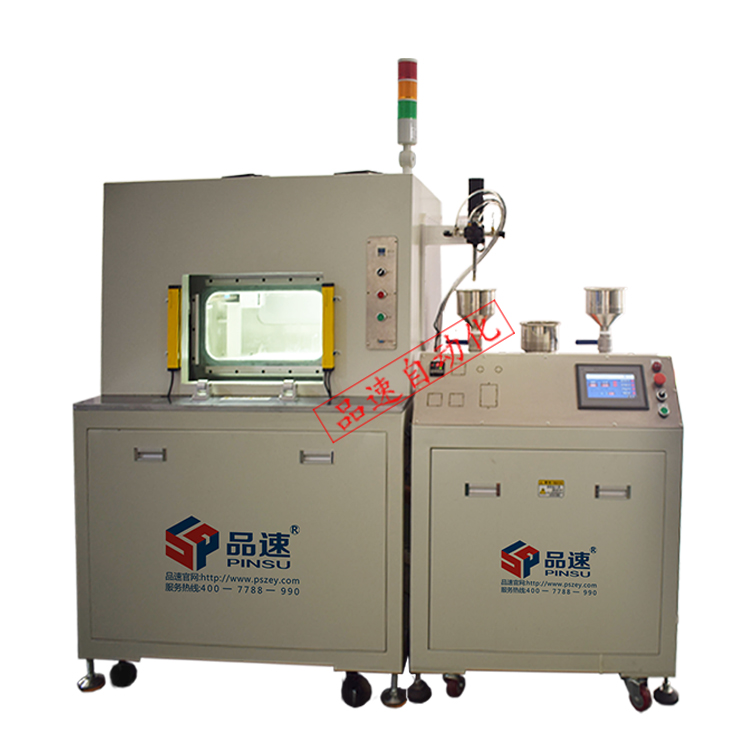

The value of a dispensing machine is mainly judged by the size and accuracy of its dispensing volume. A good dispensing equipment will determine the entire production process. Here are some methods for distinguishing dispensing machines that I have compiled for your reference.

The dispensing effect determines the value of this dispensing machine. The quality of the dispensing product is directly related to the control of the dispensing amount of the dispensing machine, and the effect of dispensing amount control is not only related to the set parameters, but also inevitably related to the maintenance of the automatic dispensing machine. The reasons for poor control of the dispensing volume of automatic dispensing machines are as follows:

1. The air pressure in the trachea is insufficient, and the effect of controlling the amount of glue used is not significant。

2. There is a phenomenon of leakage and insufficient glue output.

3. The dispensing needle was not cleaned thoroughly, causing blockage during secondary use.

The air pressure during the operation of the automatic dispensing machine should be controlled within an appropriate range, and there should be no overpressure or low-pressure. If the air pressure is not within the range of use, it is easy to cause poor dispensing volume. The main reason is that insufficient air pressure occurs when the pressure tank of the dispensing machine is unstable. The inlet pressure gauge should be adjusted to about 11 to 14 psi, and the air pipe pressure should be above the dispensing volume control that the automatic dispensing machine meets.

The main reason for dripping during the dispensing process of the dispensing machine is that the concentration of the glue is not enough, which causes the glue to flow down along the needle during dispensing. As long as the vacuum suction function is added, the pressure difference inside the dispensing valve relative to the external atmospheric pressure can be utilized to close the dispensing valve and achieve the control of the dispensing volume. In order to improve the control of the dispensing volume, maintenance work needs to be carried out on the dispensing machine.

If you need to use an automatic dispensing machine to complete special arc dispensing, in addition to controlling the dispensing volume, you also need to program the arc path through the dispensing controller to improve the dispensing quality. After long-term arc path dispensing, the repeatability accuracy will be affected. Therefore, maintenance and adjustment of the automatic dispensing machine can improve the quality of arc dispensing.

The dispensing effect determines the value of this dispensing machine. The quality of the dispensing product is directly related to the control of the dispensing amount of the dispensing machine, and the effect of dispensing amount control is not only related to the set parameters, but also inevitably related to the maintenance of the automatic dispensing machine. The reasons for poor control of the dispensing volume of automatic dispensing machines are as follows:

1. The air pressure in the trachea is insufficient, and the effect of controlling the amount of glue used is not significant。

2. There is a phenomenon of leakage and insufficient glue output.

3. The dispensing needle was not cleaned thoroughly, causing blockage during secondary use.

The air pressure during the operation of the automatic dispensing machine should be controlled within an appropriate range, and there should be no overpressure or low-pressure. If the air pressure is not within the range of use, it is easy to cause poor dispensing volume. The main reason is that insufficient air pressure occurs when the pressure tank of the dispensing machine is unstable. The inlet pressure gauge should be adjusted to about 11 to 14 psi, and the air pipe pressure should be above the dispensing volume control that the automatic dispensing machine meets.

The main reason for dripping during the dispensing process of the dispensing machine is that the concentration of the glue is not enough, which causes the glue to flow down along the needle during dispensing. As long as the vacuum suction function is added, the pressure difference inside the dispensing valve relative to the external atmospheric pressure can be utilized to close the dispensing valve and achieve the control of the dispensing volume. In order to improve the control of the dispensing volume, maintenance work needs to be carried out on the dispensing machine.

If you need to use an automatic dispensing machine to complete special arc dispensing, in addition to controlling the dispensing volume, you also need to program the arc path through the dispensing controller to improve the dispensing quality. After long-term arc path dispensing, the repeatability accuracy will be affected. Therefore, maintenance and adjustment of the automatic dispensing machine can improve the quality of arc dispensing.

中文

中文