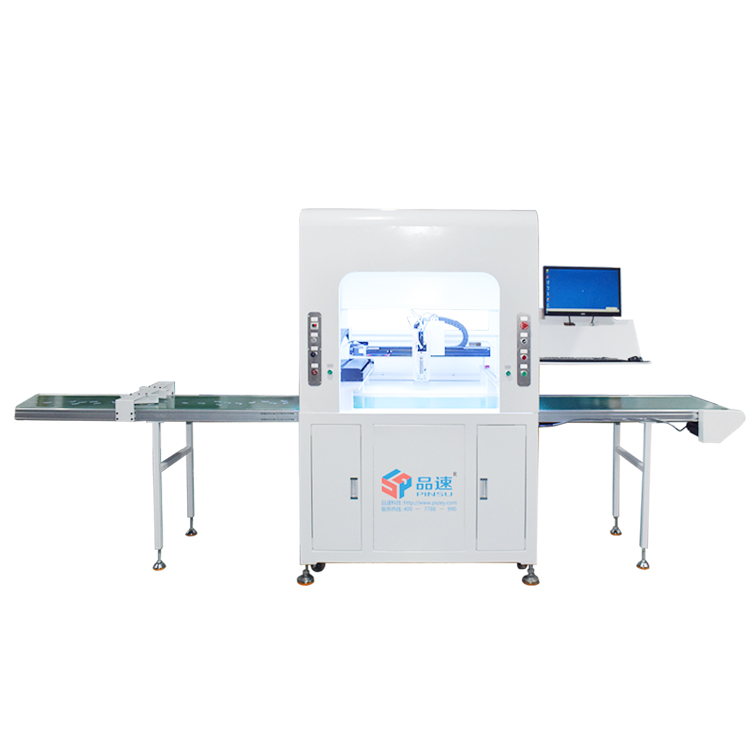

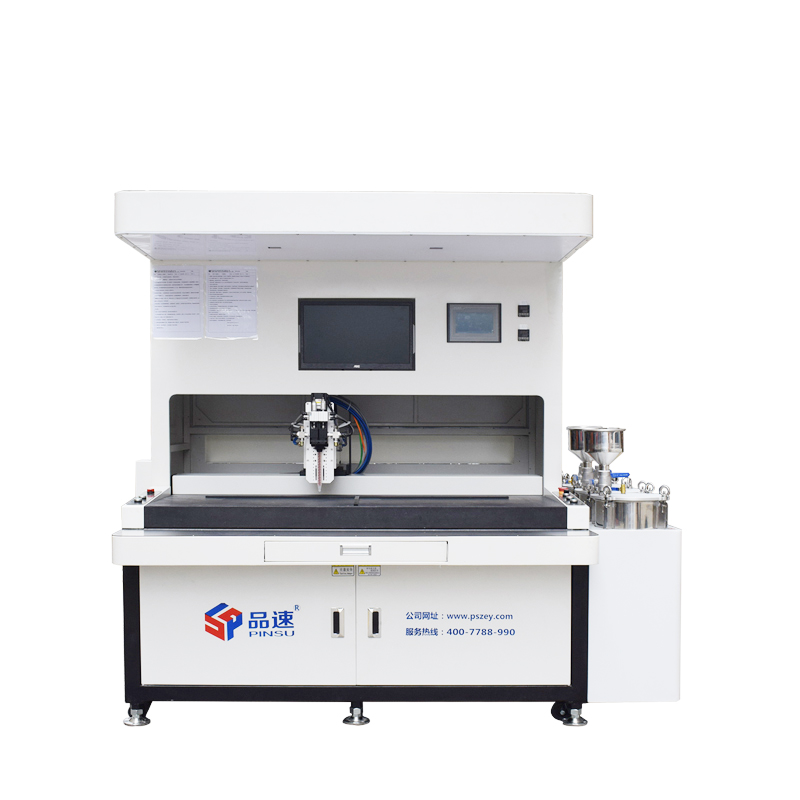

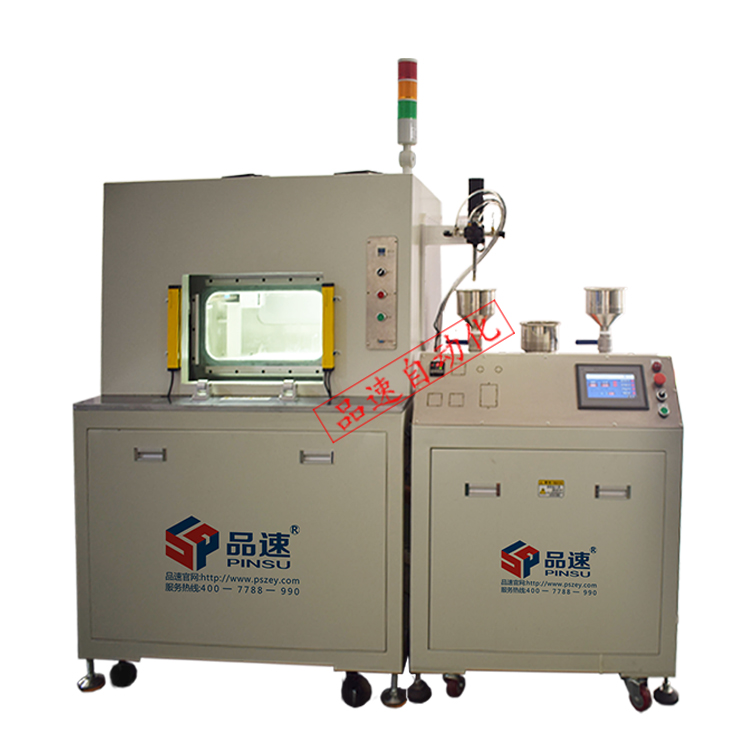

Maintenance of three-axis dispensing machine

As a high-precision automation equipment, the stability and service life of a three-axis dispensing machine are closely related to daily maintenance. A scientifically standardized maintenance process can not only improve equipment operating efficiency, but also effectively reduce failure rates and ensure the accuracy of dispensing processes. The following systematically explains the maintenance points of the product speed three-axis dispensing machine from three aspects: daily maintenance, periodic maintenance, and precautions.

1、 Daily maintenance and upkeep standards

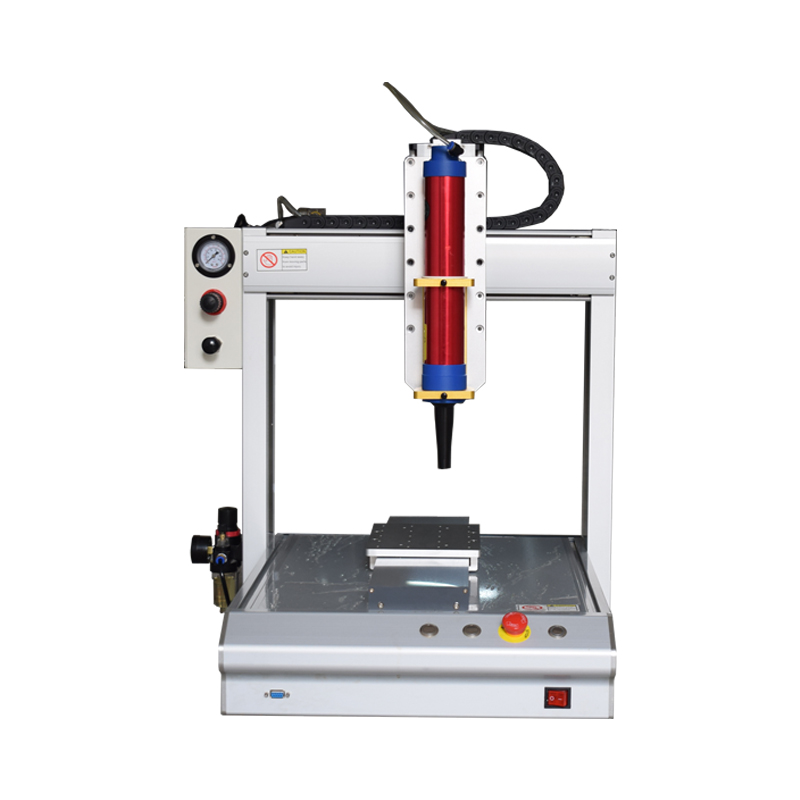

1. Mechanical system inspection

Three axis motion platform (X/Y/Z axis): Manually push the shaft body before starting up every day to confirm that there is no jamming during operation and that there is no dust or foreign object accumulation on the guide rail surface. If loose or abnormal noise is found in the screw nut, the machine should be stopped immediately for troubleshooting.

Glue dispensing head and needle: Check if the fixed bracket is displaced and if the needle is securely installed to avoid glue deviation or leakage caused by looseness.

2. Maintenance of pneumatic system

Pressure monitoring: Ensure that the pressure gauge reading of the gas source is stable within the range of 0.5-0.8 MPa. If the air pressure is insufficient, it is necessary to check the sealing of the air compressor and pipeline to avoid affecting the dispensing accuracy due to air pressure fluctuations.

Air filter (triple piece): daily discharge of condensed water in the filter, regular replacement of filter element to prevent water vapor or oil contamination from entering the air system, causing air valve blockage or corrosion.

3. Electrical system inspection

Control panel and touch screen: Test the sensitivity of button response and confirm that the touch screen displays no screen flickering or delay phenomenon.

Power and grounding: Check if the power line interface is loose, use a grounding tester to measure the grounding resistance (≤ 4 Ω), and ensure the safe operation of the equipment.

4. Cleaning of rubber road system

Single component adhesive equipment: Clean the adhesive valve, pipeline, and needle with specialized solvents (such as acetone, toluene, etc., depending on the type of adhesive) after daily operation, and discharge residual adhesive through air pressure.

Two component glue equipment: After separating the A/B glue paths, clean them separately. The dynamic mixing tube needs to be disassembled and soaked for 15 minutes before rinsing to avoid blockage by solidified materials. After cleaning, run the equipment for 5 minutes to ensure that there is no solvent residue on the rubber path.

1. Weekly in-depth maintenance

Pneumatic system: Disassemble the air filter and replace the filter element; Check the elasticity of the pressure reducing valve spring. If the wear exceeds 1mm, it needs to be replaced to ensure that the filtration accuracy is ≤ 5 μ m and the pressure fluctuation is ≤ ± 0.05MPa.

Drive cooling: Clean the dust on the drive fan grille, blow the internal heat sink with compressed air (≤ 0.3MPa) to ensure that the fan speed is ≥ 2000rpm and the drive temperature is ≤ 50 ℃.

2. Monthly comprehensive inspection

Lubrication of guide rails and screws: Apply lithium based grease and replenish every 8 hours of operation to reduce mechanical wear.

Limit switch and emergency stop button: Test the sensitivity of the limit switch and the effectiveness of the emergency stop function to prevent abnormal operation of the equipment.

sensor calibration

Liquid level and pressure sensors: Regularly calibrate the sensor readings. If the deviation exceeds ± 5%, recalibration is required to ensure that the liquid level detection error is ≤ 1mm and the pressure detection error is ≤ ± 0.02MPa.

3、 Key precautions

1. Operating standards

When changing the adhesive type: thoroughly clean the pipeline to avoid mixing and reacting different adhesives. Close the feed valve, open the discharge valve to discharge residual glue, and then rinse with a circulating cleaning solvent.

Mobile devices: Cut off the power and air circuit before operation to prevent accidents caused by abnormal air pressure or circuit.

2. Environmental management

Ventilation and dust prevention: The equipment should be placed in a dry and ventilated area to avoid dust accumulation, which may cause short circuits in the circuit or rusting of mechanical components.

Power outage protection: Cut off the power when continuously stopped. It is recommended to turn on the machine every two days to prevent glue crystallization or motor power failure and locking.

3. Component maintenance

Glue valve body: Do not use metal tools to scratch the surface of components, instead use cleaning agents to soak and soften residual colloids.

Raw material bucket filter: Regularly clean or replace to prevent impurities from entering the rubber system.

4、 Professional optimization suggestions

1. Operation training: Ensure that operators master the equipment operation rules and emergency response procedures, reducing the risk of human error.

2. Preventive maintenance: Develop a maintenance schedule, record the details of each maintenance, and dynamically adjust the maintenance cycle based on the frequency of equipment use.

3. Spare parts management: Keep readily available vulnerable parts (such as rubber nozzles, filter cartridges, sealing rings, etc.) to shorten downtime due to malfunctions.

4. By strictly following the above maintenance process, the Pin Speed three-axis glue dispensing machine can maintain high-precision and high stability operation for a long time, significantly extending equipment life. 5. It is recommended that enterprises further refine maintenance standards based on their own production needs, incorporate equipment maintenance into standardized management systems, and maximize the efficiency of automated equipment.

1、 Daily maintenance and upkeep standards

1. Mechanical system inspection

Three axis motion platform (X/Y/Z axis): Manually push the shaft body before starting up every day to confirm that there is no jamming during operation and that there is no dust or foreign object accumulation on the guide rail surface. If loose or abnormal noise is found in the screw nut, the machine should be stopped immediately for troubleshooting.

Glue dispensing head and needle: Check if the fixed bracket is displaced and if the needle is securely installed to avoid glue deviation or leakage caused by looseness.

2. Maintenance of pneumatic system

Pressure monitoring: Ensure that the pressure gauge reading of the gas source is stable within the range of 0.5-0.8 MPa. If the air pressure is insufficient, it is necessary to check the sealing of the air compressor and pipeline to avoid affecting the dispensing accuracy due to air pressure fluctuations.

Air filter (triple piece): daily discharge of condensed water in the filter, regular replacement of filter element to prevent water vapor or oil contamination from entering the air system, causing air valve blockage or corrosion.

3. Electrical system inspection

Control panel and touch screen: Test the sensitivity of button response and confirm that the touch screen displays no screen flickering or delay phenomenon.

Power and grounding: Check if the power line interface is loose, use a grounding tester to measure the grounding resistance (≤ 4 Ω), and ensure the safe operation of the equipment.

4. Cleaning of rubber road system

Single component adhesive equipment: Clean the adhesive valve, pipeline, and needle with specialized solvents (such as acetone, toluene, etc., depending on the type of adhesive) after daily operation, and discharge residual adhesive through air pressure.

Two component glue equipment: After separating the A/B glue paths, clean them separately. The dynamic mixing tube needs to be disassembled and soaked for 15 minutes before rinsing to avoid blockage by solidified materials. After cleaning, run the equipment for 5 minutes to ensure that there is no solvent residue on the rubber path.

1. Weekly in-depth maintenance

Pneumatic system: Disassemble the air filter and replace the filter element; Check the elasticity of the pressure reducing valve spring. If the wear exceeds 1mm, it needs to be replaced to ensure that the filtration accuracy is ≤ 5 μ m and the pressure fluctuation is ≤ ± 0.05MPa.

Drive cooling: Clean the dust on the drive fan grille, blow the internal heat sink with compressed air (≤ 0.3MPa) to ensure that the fan speed is ≥ 2000rpm and the drive temperature is ≤ 50 ℃.

2. Monthly comprehensive inspection

Lubrication of guide rails and screws: Apply lithium based grease and replenish every 8 hours of operation to reduce mechanical wear.

Limit switch and emergency stop button: Test the sensitivity of the limit switch and the effectiveness of the emergency stop function to prevent abnormal operation of the equipment.

sensor calibration

Liquid level and pressure sensors: Regularly calibrate the sensor readings. If the deviation exceeds ± 5%, recalibration is required to ensure that the liquid level detection error is ≤ 1mm and the pressure detection error is ≤ ± 0.02MPa.

3、 Key precautions

1. Operating standards

When changing the adhesive type: thoroughly clean the pipeline to avoid mixing and reacting different adhesives. Close the feed valve, open the discharge valve to discharge residual glue, and then rinse with a circulating cleaning solvent.

Mobile devices: Cut off the power and air circuit before operation to prevent accidents caused by abnormal air pressure or circuit.

2. Environmental management

Ventilation and dust prevention: The equipment should be placed in a dry and ventilated area to avoid dust accumulation, which may cause short circuits in the circuit or rusting of mechanical components.

Power outage protection: Cut off the power when continuously stopped. It is recommended to turn on the machine every two days to prevent glue crystallization or motor power failure and locking.

3. Component maintenance

Glue valve body: Do not use metal tools to scratch the surface of components, instead use cleaning agents to soak and soften residual colloids.

Raw material bucket filter: Regularly clean or replace to prevent impurities from entering the rubber system.

4、 Professional optimization suggestions

1. Operation training: Ensure that operators master the equipment operation rules and emergency response procedures, reducing the risk of human error.

2. Preventive maintenance: Develop a maintenance schedule, record the details of each maintenance, and dynamically adjust the maintenance cycle based on the frequency of equipment use.

3. Spare parts management: Keep readily available vulnerable parts (such as rubber nozzles, filter cartridges, sealing rings, etc.) to shorten downtime due to malfunctions.

4. By strictly following the above maintenance process, the Pin Speed three-axis glue dispensing machine can maintain high-precision and high stability operation for a long time, significantly extending equipment life. 5. It is recommended that enterprises further refine maintenance standards based on their own production needs, incorporate equipment maintenance into standardized management systems, and maximize the efficiency of automated equipment.

中文

中文