Maintenance of glue filling machine

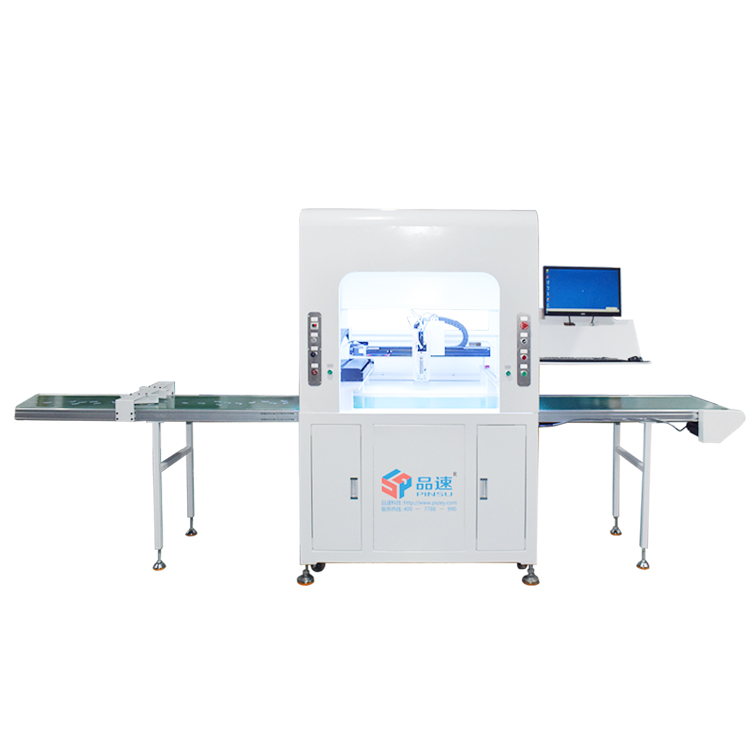

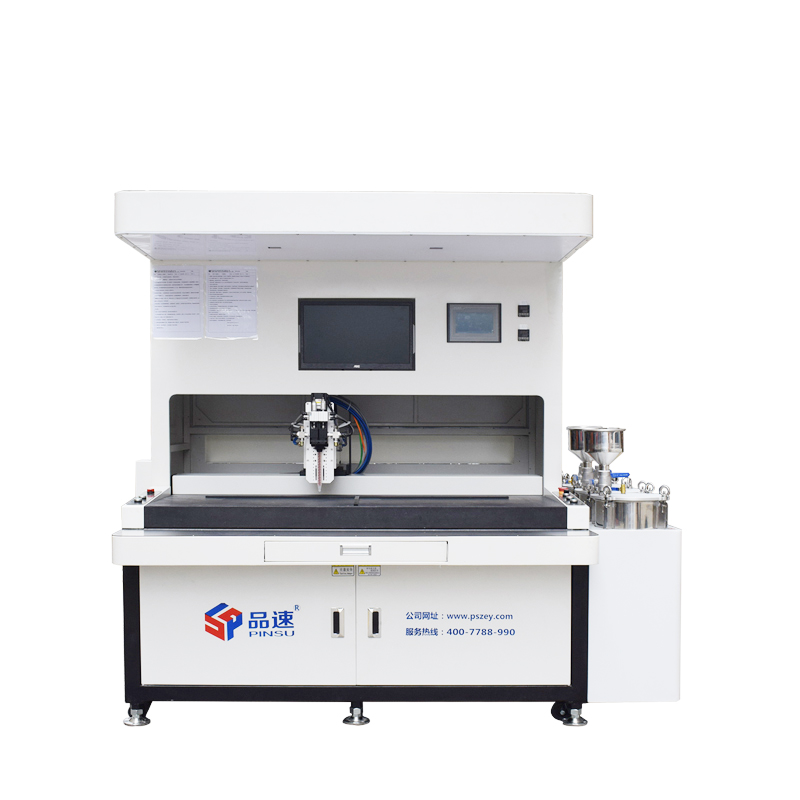

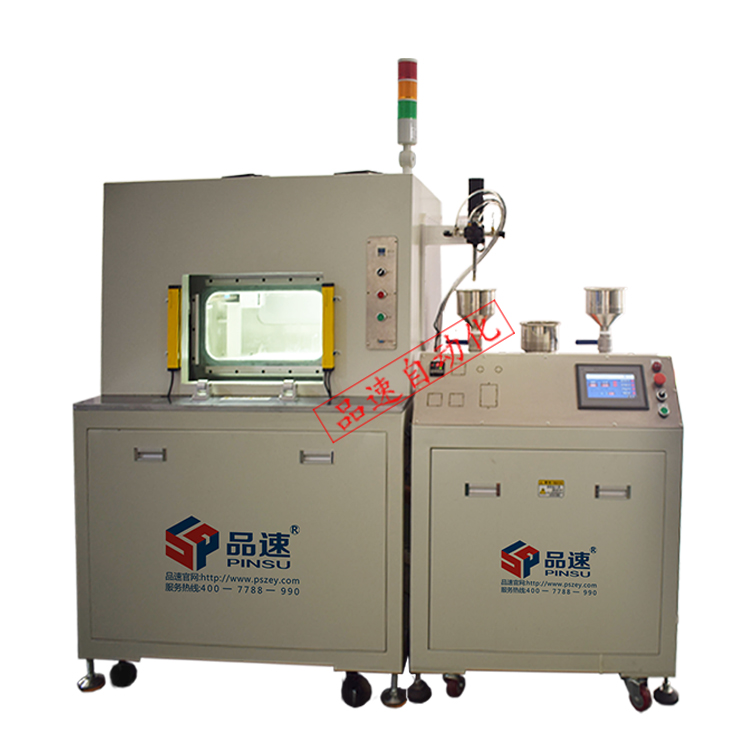

As a precision automation equipment, the operating efficiency of the glue filling machine is closely related to the removal of glue residue. The product speed glue filling machine has designed a standardized cleaning process for different types of glue and process requirements, balancing the flexibility of automated operation and manual maintenance to ensure long-term stable operation of the equipment.

1、 Automatic cleaning process: efficient and convenient, precise pollution control

The product speed glue filling machine comes standard with intelligent cleaning function, which achieves rapid purification of the glue path system through a three-step process:

1. Air pressure blowing: After starting the cleaning program, the equipment first blows the mixing pipe, glue valve, and nozzle with compressed air (0.5-0.6MPa) to preliminarily remove uncured glue and avoid residual blockage.

2. Solvent flushing: Inject specialized cleaning agents (such as plate washing water, acetone, etc.), circulate and flush the glue path through a pumping system, and use the solvent to dissolve and solidify the gel. The amount of cleaning solution is set according to the capacity of the rubber drum (default 300g) to ensure coverage of all contact surfaces.

3. Secondary blowing: Introduce clean air again to thoroughly remove residual solvents and loose particles, preventing secondary pollution caused by residual cleaning solution.

1. Disassemble and soak:

Remove the mixing tube, nozzle, and metering pump components, immerse them in a 304 stainless steel cleaning bucket, add dichloromethane, ethyl acetate, or alcohol (depending on the type of adhesive), and let it stand for 10-15 minutes to soften the residual colloid.

Gently brush the inner wall with a soft bristled brush to avoid scratching the surface of precision components with hard objects.

2. Dynamic cycle cleaning:

Pour the cleaning solution into the glue bucket, start the equipment circulation pump, and let the solvent flow in the pipeline for 10-20 minutes to ensure that there is no residue in the dead corner.

For two-component adhesive systems, it is necessary to clean the A/B adhesive paths separately to avoid mixing reactions and the formation of cured products.

3. Drying and reassembly:

Blow dry the components with compressed air or place them in a constant temperature box (50-60 ℃) to accelerate evaporation.

Check if the O-ring and sealing gasket are intact during reassembly to prevent glue leakage.

III The product speed glue filling machine is compatible with multiple cleaning agents and needs to be flexibly selected according to the characteristics of the glue and environmental protection requirements:

1. Epoxy resin adhesive: Acetone or dichloromethane are recommended as they have strong solubility, but ventilation and volatilization prevention should be taken into account; Acetone is corrosive to some plastic parts, it is recommended to wipe them clean after a short period of contact.

2. Polyurethane PU adhesive: Tianna water or ethyl acetate has a significant effect. Tianna water has excellent solubility but is controlled by some regions. Ethyl acetate has low toxicity and is suitable for closed workshops.

3. Silicone: Special silicone cleaning agent can prevent impurities from reacting with strong acidic and alkaline solvents and metal parts.

4. Environmental reminder: Prioritize the use of recyclable solvents (such as environmentally friendly degreasing agents) to reduce VOC emissions and comply with green production standards.

4、 Key precautions: Avoid risks and ensure safety

1. Power off operation: Before cleaning, be sure to turn off the power and gas sources of the equipment to prevent mechanical damage or personal injury caused by accidental start-up.

2. Solvent protection: Wear solvent resistant gloves, goggles, and gas masks to avoid skin contact or inhalation of harmful gases.

3. Residual glue treatment: Waste solvents and glue residue need to be classified and collected in dedicated recycling bins, and treated according to hazardous waste standards to avoid environmental pollution.

4. Sealing inspection: After cleaning and reassembly, focus on checking the sealing ring of the rubber drum cover, the joint of the mixing pipe, and other parts to ensure no leakage.

5、 Long term maintenance recommendations

1. Regular maintenance: Establish a cleaning schedule (such as basic cleaning after daily work and deep maintenance every week) to avoid prolonged solidification of colloids.

2. Preventive replacement: It is recommended to replace vulnerable parts (such as filters and seals) every 3 months to reduce the risk of sudden failures.

3. Record management: Establish equipment cleaning logs to record cleaning time, solvent usage, and abnormal situations, providing data support for subsequent optimization.

By strictly adhering to the cleaning standards of the speed dispensing machine, the service life of the equipment can be effectively extended, ensuring dispensing accuracy and production efficiency. It is recommended that users flexibly adjust their cleaning strategies based on specific process requirements, and regularly invite professional engineers for in-depth maintenance to maximize the value of the equipment.

1、 Automatic cleaning process: efficient and convenient, precise pollution control

The product speed glue filling machine comes standard with intelligent cleaning function, which achieves rapid purification of the glue path system through a three-step process:

1. Air pressure blowing: After starting the cleaning program, the equipment first blows the mixing pipe, glue valve, and nozzle with compressed air (0.5-0.6MPa) to preliminarily remove uncured glue and avoid residual blockage.

2. Solvent flushing: Inject specialized cleaning agents (such as plate washing water, acetone, etc.), circulate and flush the glue path through a pumping system, and use the solvent to dissolve and solidify the gel. The amount of cleaning solution is set according to the capacity of the rubber drum (default 300g) to ensure coverage of all contact surfaces.

3. Secondary blowing: Introduce clean air again to thoroughly remove residual solvents and loose particles, preventing secondary pollution caused by residual cleaning solution.

2、 Manual cleaning method: deep processing, flexible response to complex working conditions

The glue filling machine will not be used for a period of time and requires manual cleaning of pipelines, metering pumps, material buckets, mixing valves, etc., to avoid glue sedimentation and solidification:1. Disassemble and soak:

Remove the mixing tube, nozzle, and metering pump components, immerse them in a 304 stainless steel cleaning bucket, add dichloromethane, ethyl acetate, or alcohol (depending on the type of adhesive), and let it stand for 10-15 minutes to soften the residual colloid.

Gently brush the inner wall with a soft bristled brush to avoid scratching the surface of precision components with hard objects.

2. Dynamic cycle cleaning:

Pour the cleaning solution into the glue bucket, start the equipment circulation pump, and let the solvent flow in the pipeline for 10-20 minutes to ensure that there is no residue in the dead corner.

For two-component adhesive systems, it is necessary to clean the A/B adhesive paths separately to avoid mixing reactions and the formation of cured products.

3. Drying and reassembly:

Blow dry the components with compressed air or place them in a constant temperature box (50-60 ℃) to accelerate evaporation.

Check if the O-ring and sealing gasket are intact during reassembly to prevent glue leakage.

III The product speed glue filling machine is compatible with multiple cleaning agents and needs to be flexibly selected according to the characteristics of the glue and environmental protection requirements:

1. Epoxy resin adhesive: Acetone or dichloromethane are recommended as they have strong solubility, but ventilation and volatilization prevention should be taken into account; Acetone is corrosive to some plastic parts, it is recommended to wipe them clean after a short period of contact.

2. Polyurethane PU adhesive: Tianna water or ethyl acetate has a significant effect. Tianna water has excellent solubility but is controlled by some regions. Ethyl acetate has low toxicity and is suitable for closed workshops.

3. Silicone: Special silicone cleaning agent can prevent impurities from reacting with strong acidic and alkaline solvents and metal parts.

4. Environmental reminder: Prioritize the use of recyclable solvents (such as environmentally friendly degreasing agents) to reduce VOC emissions and comply with green production standards.

4、 Key precautions: Avoid risks and ensure safety

1. Power off operation: Before cleaning, be sure to turn off the power and gas sources of the equipment to prevent mechanical damage or personal injury caused by accidental start-up.

2. Solvent protection: Wear solvent resistant gloves, goggles, and gas masks to avoid skin contact or inhalation of harmful gases.

3. Residual glue treatment: Waste solvents and glue residue need to be classified and collected in dedicated recycling bins, and treated according to hazardous waste standards to avoid environmental pollution.

4. Sealing inspection: After cleaning and reassembly, focus on checking the sealing ring of the rubber drum cover, the joint of the mixing pipe, and other parts to ensure no leakage.

5、 Long term maintenance recommendations

1. Regular maintenance: Establish a cleaning schedule (such as basic cleaning after daily work and deep maintenance every week) to avoid prolonged solidification of colloids.

2. Preventive replacement: It is recommended to replace vulnerable parts (such as filters and seals) every 3 months to reduce the risk of sudden failures.

3. Record management: Establish equipment cleaning logs to record cleaning time, solvent usage, and abnormal situations, providing data support for subsequent optimization.

By strictly adhering to the cleaning standards of the speed dispensing machine, the service life of the equipment can be effectively extended, ensuring dispensing accuracy and production efficiency. It is recommended that users flexibly adjust their cleaning strategies based on specific process requirements, and regularly invite professional engineers for in-depth maintenance to maximize the value of the equipment.

中文

中文